Hage Matic Gantry

processing centres

PROCESSING OF LARGE STEEL AND ALUMINIUM SECTIONS

HAGE Matic CNC gantry processing centres are made for high-precision processing of large steel and aluminium sections. The workpieces can have a total length of up to 100 m.

The gantry processing centres can combine multiple processing technologies, for example milling and FSW. There are effectively no limits as to the control system, since the controls are compatible with all of the common CNC systems. Depending on the needs of individual customers, HAGE also supplies

- Safety and noise control concepts

- Efficient swarf management

- Clamping systems

- NC programmes optimized for specific workpieces

- Specifications for the machine foundation

HAGE Matic machines are as diverse as the workpieces they process. Beginning from our two basic machine concepts, HAGE Matic Classic and HAGE Matic Flexible, we develop customized machines in close consultation with our customers.

HAGE Matic gantry processing centres are made for processing large aluminum and steel sections.

HAGE

technology

centre

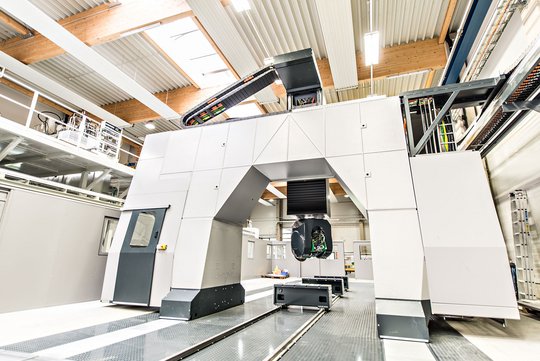

5-Axis gantry processing centre

(including FSW process and process monitoring)

used for development, demonstration and contract manufacturing

Range of travel: 20 m x 3 m x 1,6 m

GANTRY PROCESSING CENTRE

AS A COMPLETE SOLUTION

In line with our ‘full service’ concept, we support customers from the initial consultation until commissioning of the machine – and beyond, with maintenance and service.

HAGE Matic machines are in use around the world and are valued for their precision and ease of use. Our reference customers include major manufacturers of rail vehicles.

HAGE matic

classic

Milling, drilling, saw cutting, thread cutting: HAGE Matic Classic is a 5-axis gantry milling machine for aluminium and steel sections.

MACHINEN HIGHLIGHTS:

- Individual milling head and spindle specifications

- Double rails in the x-axis

- Gantry milling machine with tool changer

- 5-sided processing

- Hybrid construction enables the combination of multiple processing technologies

- All common CNC systems can be used

The double rails in the X-axis enable the machine to work on parts up to 100 m long and 6 m wide. The milling head and spindle specifications are worked out individually. The gantry structure, which is optimized by finite-element analysis, is adapted to suit the width of the workpieces.

HAGE matic

Flexible

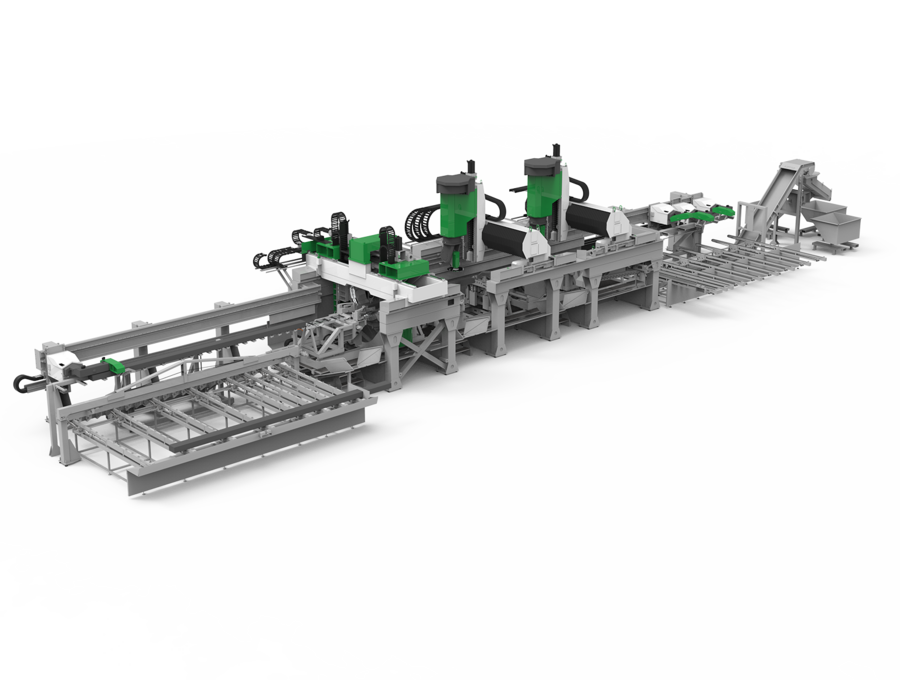

The highest level of customization is available in the form of our HAGE Matic Flexible line. These fully automatic processing centres are used, for example, in the production of metal sections for window and conservatory frames and roller shutters.

AVAILABLE LINE COMPONENTS:

- Flat magazine

- Feed roller conveyor

- Profile check

- 5 NC feed grippers

- Processing centre with 8 spindles

- 2 pieces 5-axis processing centres

- Clamping fixture for profiles

- Output roller conveyor

- Outfeed buffer

- Chip disposal

An innovative example of a HAGE Matic Flexible is the automatic processing centre for window frames.

The workpieces are loaded into the processing centre by hand. At the end of the conveyor the profiles are put into the right position. A total of five feed gripper safes the further transport of the workpieces through the line.

The first of two processing centres provides eight processing heads which are build up on a positioning unite. The spindle is able to reach every positions across the profile, so a tool change is not necessary. The second processing centre realizes the front side processing with a tilting head. The workpieces are cut and a cutting gripper transport the finished parts to the outfeed buffer. Straight cuts, mitre cuts or different angles up to +/- 45° are possible.