The FSW welding process creates very high-quality joints between parts made of aluminium alloys and mixed materials. It is sufficiently reliable for use as a routine, automated process and plays a key role in lightweight construction of rail and road vehicles, aeroplanes, space vehicles and ships, as well as in construction of industrial plant.

HAGE FSW solutions are based on a basic portfolio of machine concepts that are designed to optimize the welding process. The FSW machines are customized to meet individual customers’ needs and can be made in column or gantry configurations. HAGE machine designs focus on achieving very high rigidity and perfect clamping systems.

In every project that we take on for our customers, our ambition is to achieve a process that yields precisely dimensioned workpieces and excellent welding. HAGE FSW experts support you from initial consultations through whatever experiments and feasibility studies may be needed. Our in-house pilot plant is available for testing and development work, and production of initial sample pieces.

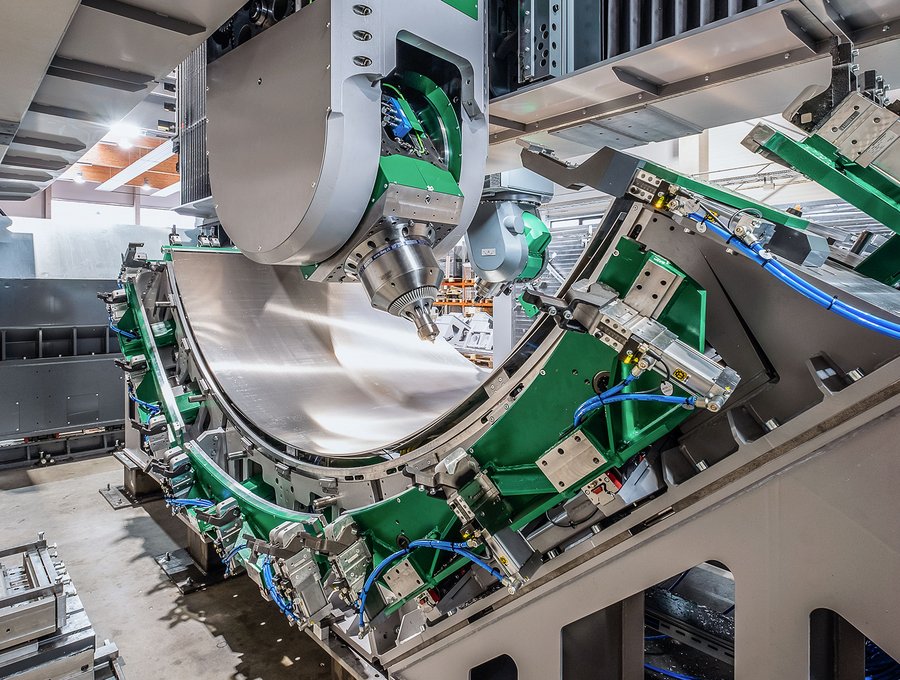

HAGE FSW technology centre

for development, demonstration and contract manufacturing

Range of travel: 20 m x 3 m x 1,6 m

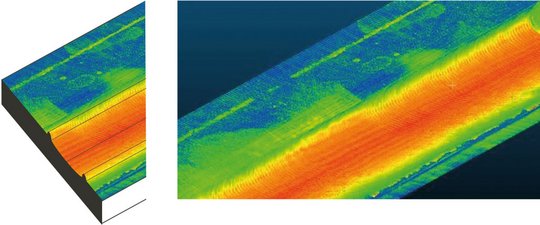

- Online process monitoring and error analysis

- Geometric monitoring as a quality factor and for process optimisation

- Real-time visualisation of the measured parameters

- Unique identification of all welds

- Fully automatic generation of post-processor data

- Raw data saved for offline viewing and analysis

- Analysis using standards-based rules

- Archivable document generated for long-term storage and quality assurance

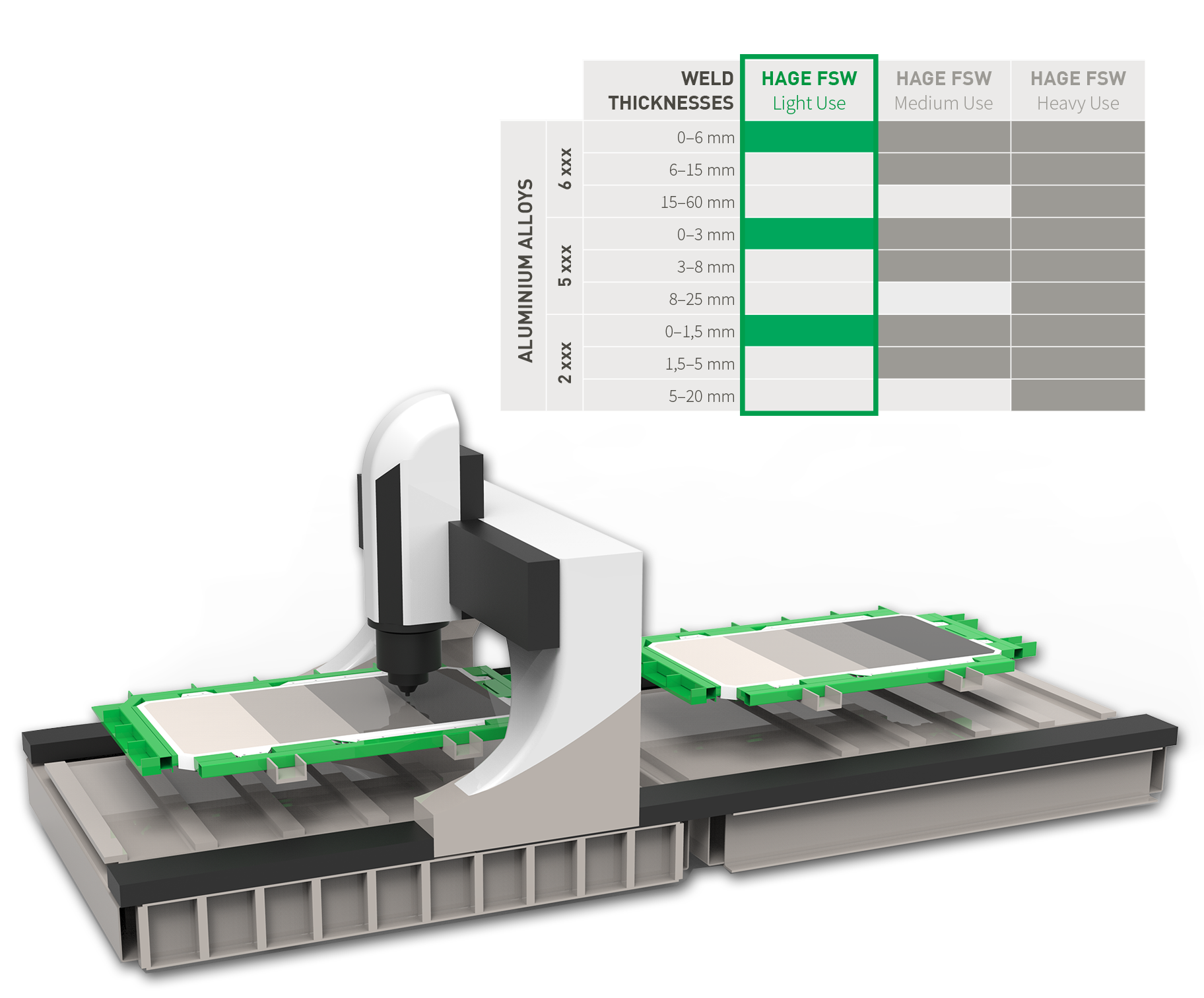

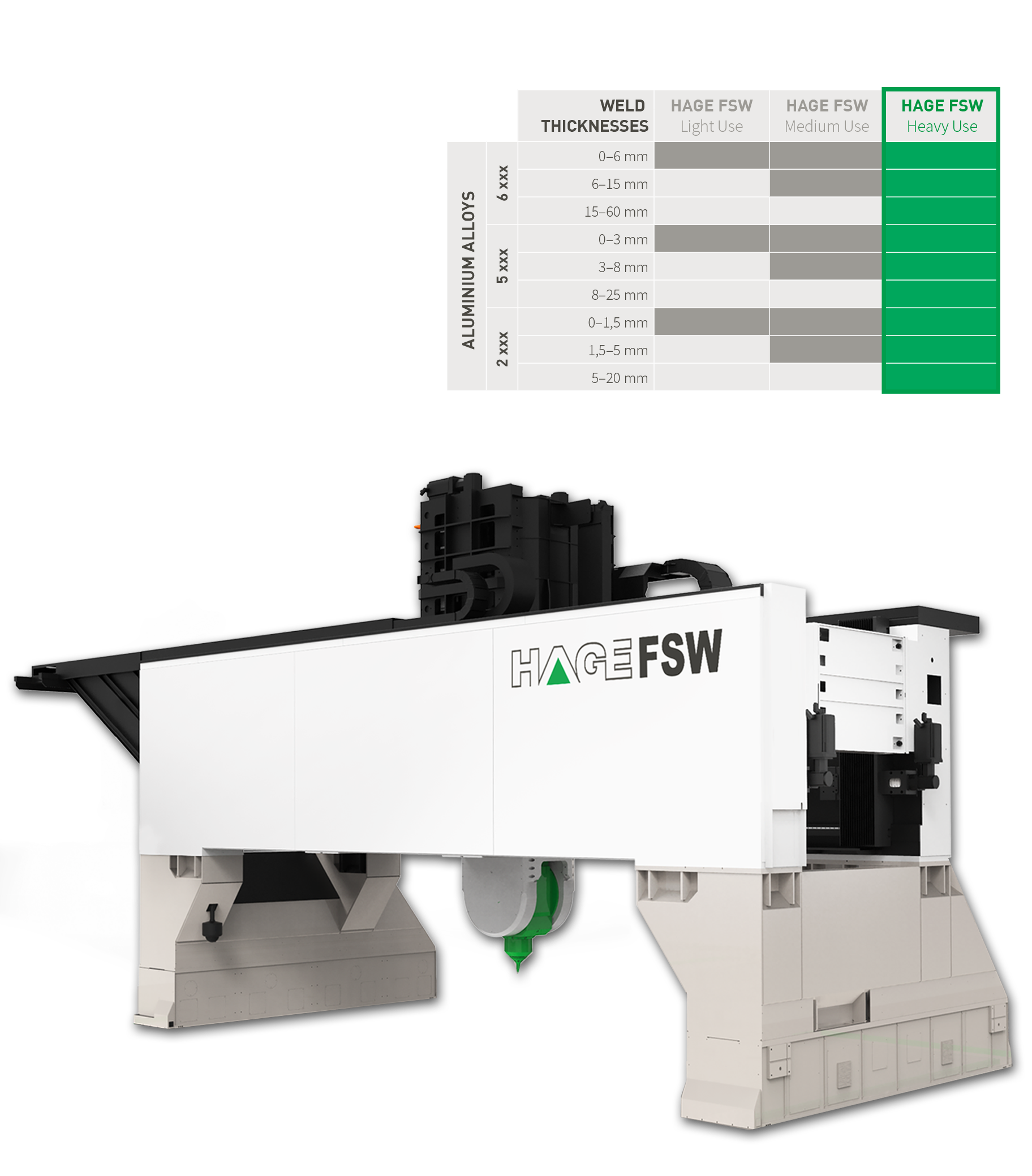

HAGE FSW

Light use

The HAGE FSW Light Use was developed specially for the automotive industry and delivers perfect welding results.

MACHINE HIGHLIGHTS:

- Highly rigid, FEM-calculated machine frame design

- Siemens 840Dsl or FANUC CNC, safety integrated

- Force measurement system

- Path and force control

- Adjustable tilt angles (optionally also via an NC axis)

- C axis for positioning the FSW spindle

- Process monitoring using HAGE FSW WeldCheck

TECHNICAL DATA:

Range of travel

X-axis: up to 5,000 mm

Y-axis: up to 2,500 mm

Z-axis: up to 700 mm

Feed rate

X-axis: 5–40,000 mm/min

Y-axis: 5–40,000 mm/min

Z-axis: 5–30,000 mm/min

C-axis: up to 15°/s

Tilt angle

C-axis: 400° (+/– 200°)

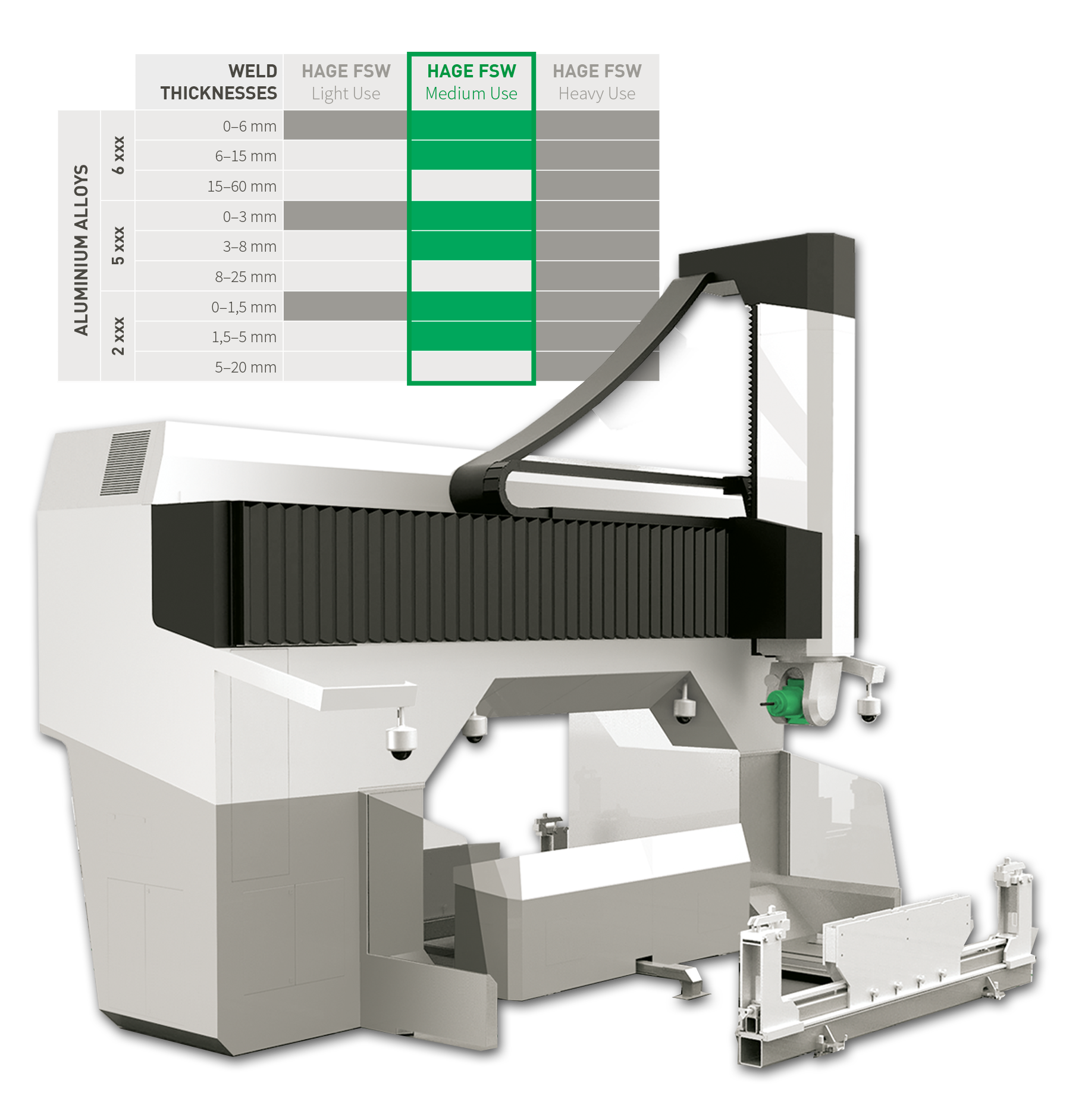

HAGE FSW

Medium use

The HAGE FSW Medium Use is a medium-sized 5-axis FSW machine for processing of large metal sections. It is also available as a hybrid version for milling and FSW. It has an integrated automatic tool changing system.

MACHINE HIGHLIGHTS:

- Highly rigid, FEM-calculated machine frame design

- Hybrid version enables milling (with 5 NC axes) as well as welding

- 5-sided processing (milling, drilling, thread cutting, saw cutting)

- Process monitoring using HAGE FSW WeldCheck

TECHNICAL DATA:

Range of travel

X-axis: up to 80,000 mm

Y-axis: up to 6,000 mm

Z-axis: up to 2.000 mm

Feed rate

X-axis: 5–40,000 mm/min

Y-axis: 5–40,000 mm/min

Z-axis: 5–20,000 mm/min

A-axis: up to 60°/S

C-axis: up to 60°/S

Tilt angle

A-axis: 200° (+/– 100°)

C-axis: 400° (+/– 200°)

HAGE FSW

Heavy use

The HAGE FSW Heavy Use can weld aluminium alloy parts up to 35 mm thick. It is available in both gantry and column configurations. The machine design also allows the optional integration of full-function milling, by adding an additional milling head.

MACHINE HIGHLIGHTS:

- FSW Anlage with 7 NC axes (5 linear axes and 2 rotation axes)

- Separate axes for pin and shoulder

- Path-force control for both pin and shoulder

- Measuring systems for all relevant process parameters

- Self-reacting/bobbin tools

- Inline 3D weld scanning

- Automatic NC code generation for optimal deburring

- Process monitoring using HAGE FSW WeldCheck

TECHNICAL DATA:

Range of travel

X-axis: up to 80,000 mm

Y-axis: up to 6,000 mm

Z-axis: up to 2,000 mm

FSW main spindle (one example)

Speed: up to 1,500 rpm

Torque: 302 Nm

Max. axial force: 80 kN

Max. radial force: 30 kN

FSW feed rate:

X-axis: 40,000 mm/min

Y-axis: 10,000 mm/min

Z-axis: 10,000 mm/min

A-axis: 3°/s

C-axis: 10°/s

Milling feed rate

X-axis: 40,000 mm/min

Y-axis: 40,000 mm/min

Z-axis: 20,000 mm/min

A-axis: 60°/s

C-axis: 60°/s

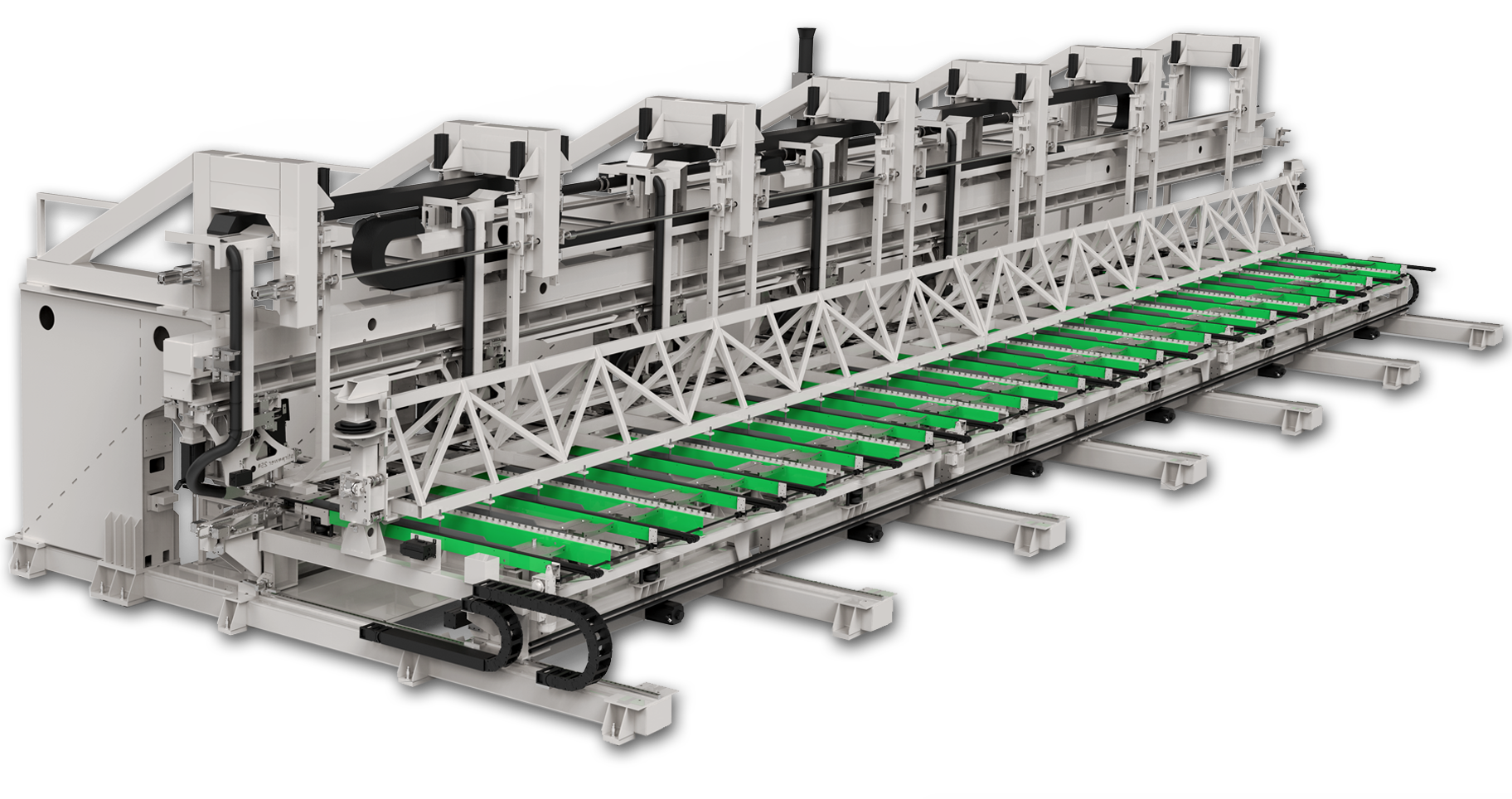

HAGE FSW

Flexible use

HAGE FSW Flexible Use special solutions offer the highest level of customization in this machine series.

HAGE FSW Flexible Use machines can be integrated into automated production lines. To increase production rates, the loading and unloading of the workpieces can be automated, via feed and unloading buffers or with unloading into transport containers. If you use raw materials that come with larger tolerances than the final product, calibration and trimming steps (saw cutting/milling) can be included so that they enter the FSW station with optimal dimensions and alignment.

If there is an urgent need to reduce cycle times, it is possible to make a machine with multiple FSW heads that work simultaneously. This can substantially reduce the time needed for welding.

FSW can be used not only for linear welds but also for spot welding (Friction Stir Spot Welding, FSSW). The HAGE FSW WeldGun is our spot welding appliance.

The FSW WeldGun can be set up as a stationary machine or as a moveable attachment on robots. It is often used for spot welding vehicle chassis parts, but another application is indirect/step welds. In this case the weld can be placed on the inside of the workpiece, so that the visible surface remains completely untouched.

TECHNICAL DATA:

Max. axial force: 8 kN

Maximum gun opening: 150 mm

Speed: 3.500 U/min

Welding time: 2–3 s per spot

Total weight: 80 kg